Porosity Measurement in B4C-Nb Composite Through Digital Image Analysis and Processing

DOI:

https://doi.org/10.14295/vetor.v32i1.13687Keywords:

Advanced ceramics, Boron carbide with niobium, Porosity, Digital image processingAbstract

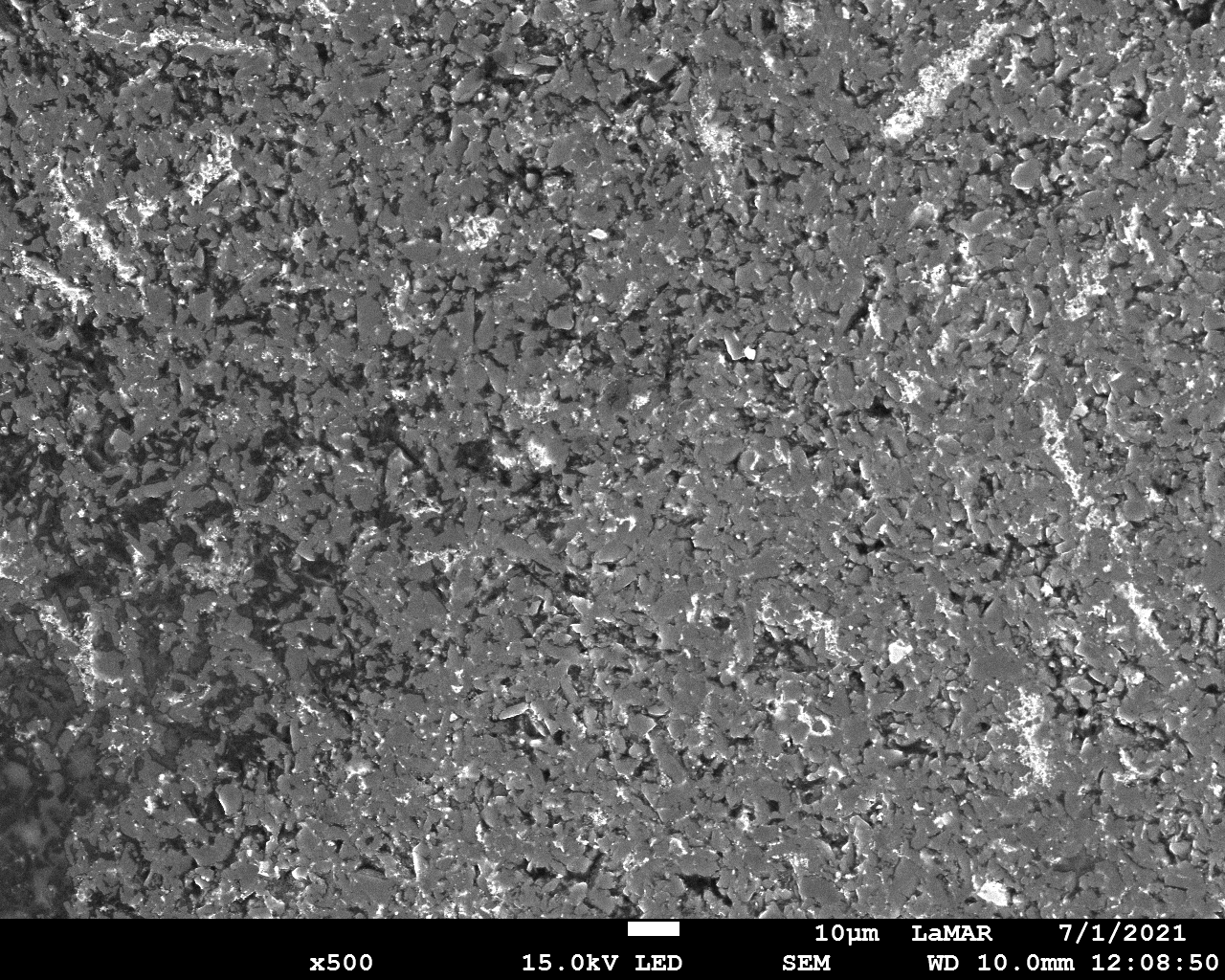

Constant research efforts have been conducted in materials selection to combine and improve the properties of interest, service life and production cost. In this context, boron carbide (B4C) stands out for having a high mechanical performance, being the material that has the fourth highest hardness (> 29.1GPa) among ceramic materials. However, porosity is seen as a limiting factor for the high performance of this group of materials, to which boron carbide is found. Porosity control is usually conducted through imprecise techniques, and indirect or costly measures for quantification. This work quantified the porosity of boron-niobium carbide (B4C-Nb) composites obtained from high pressure - high temperature (HPHT - high pressure high temperature) sintering process through analysis and digital image processing (PDI) by microscopy optical (MO) after surface preparation with controlled and automated parameters. The results obtained were compared with those obtained using the mercury intrusion porosimetry method. The semi-quantitative chemical characterization of the composites was performed using the Energy Dispersive Spectroscopy (EDS) technique.

Downloads

References

A. H. Ras, F. D. Auret, and J. M. Nel, “Boron carbide coatings on diamond particles,” Diamond and Related Materials, vol. 19, no. 11, pp. 1411–1414, 2010. Available at: https://doi.org/10.1016/j.diamond.2010.08.013.

W. Ji, R. I. Todd, W. Wang, H. Wang, J. Zhang, and Z. Fu, “Transient liquid phase spark plasma sintering of B4C-based ceramics using Ti-Al intermetallics as sintering aid,” Journal of the European Ceramic Society, vol. 36, no. 10, pp. 2419–2426, 2016. Available at: https://doi.org/10.1016/j.jeurceramsoc.2016.03.028.

G. S. Abreu, “Sinterização em alta pressão e alta temperatura (HPHT) do compósito B4C-Nb,” PhD Thesis (in Portuguese), Universidade Estadual do Norte Fluminense, Campos dos Goytacazes, Brazil, 2019. Available at: https://drive.google.com/file/d/1OvXnaYxdFufq6C4kX52tApYM7VBVbjMR/view.

V. C. Silva, “Medida de Porosidade em SiC Através de processamento digital de imagens,” Master’s Dissertation (in Portuguese), Programa de Pós-Graduação em Engenharia Mecânica, Universidade do Estado do Rio de Janeiro, Rio de Janeiro, Brazil, 2015. Available at: http://www.ppgem.uerj.br/dissertacoes.html.

R. C. Gonzalez and R. E. Woods, Processamento de imagens digitais, (in Portuguese) 1a ed.: Editora Edgard Blucher, 2000. Available at: https://www.blucher.com.br/livro/detalhes/processamento-de-imagens-digitais-770/farmacia-e-bioquimica-111.

Z. Song and Q. Y. Zhou, “Micro-scale granite permeability estimation based on digital image analysis,” Journal of Petroleum Science and Engineering, vol. 180, no. May, pp. 176–185, 2019. Available at: https://doi.org/10.1016/j.petrol.2019.05.037.

M. Uirá, “Quantificação de Defeitos por Processamento Digital de Imagens em Revestimentos obtidos por Aspersão Térmica,” Master’s Dissertation (in Portuguese), Programa de Pós-Graduação em Engenharia Mecânica, Universidade do Estado do Rio de Janeiro, Rio de Janeiro, Brazil, 2016. Available at: http://www.ppgem.uerj.br/dissertacoes.html.

H. Sun, S. Vega, and G. Tao, “Analysis of heterogeneity and permeability anisotropy in carbonate rock samples using digital rock physics,” Journal of Petroleum Science and Engineering, vol. 156, Jul. 2017, Available at: https://doi.org/10.1016/j.petrol.2017.06.002.

Downloads

Published

Versions

- 2022-07-15 (2)

- 2022-07-15 (1)